Why did I back this Kickstarter project? After all, I already have a Mosaic M1, 2 PP3DP UP! Pluses, and a Replicator 2. The main reasons were better layer resolution (0.02mm vs 0.1 for the R2) and material support. I recently saw nylon prints and found them amazing -- I bet a lot of people would love to print their own soft, custom iPhone cases! In addition, the extruder head has two nozzles -- one large diameter one for fast infill, and another small diameter one for fine details. On top of that, they will be supporting dual extruder heads soon, which means I'll be able to print support material out of dissolvable PVA and HIPS. They have put a lot of thought into the design of this machine -- only time will tell if they can deliver. I'm a beta tester, which means I'll get my unit in January 2014. I cannot wait. This machine should be truly awesome... and if it delivers, it looks like I'll have a few printers to sell soon.

Thursday, December 19, 2013

Welcome the new addition to my printing machine family

I couldn't help it. This machine looks too awesome to pass up. Let me introduce to you... Robox.

Why did I back this Kickstarter project? After all, I already have a Mosaic M1, 2 PP3DP UP! Pluses, and a Replicator 2. The main reasons were better layer resolution (0.02mm vs 0.1 for the R2) and material support. I recently saw nylon prints and found them amazing -- I bet a lot of people would love to print their own soft, custom iPhone cases! In addition, the extruder head has two nozzles -- one large diameter one for fast infill, and another small diameter one for fine details. On top of that, they will be supporting dual extruder heads soon, which means I'll be able to print support material out of dissolvable PVA and HIPS. They have put a lot of thought into the design of this machine -- only time will tell if they can deliver. I'm a beta tester, which means I'll get my unit in January 2014. I cannot wait. This machine should be truly awesome... and if it delivers, it looks like I'll have a few printers to sell soon.

Why did I back this Kickstarter project? After all, I already have a Mosaic M1, 2 PP3DP UP! Pluses, and a Replicator 2. The main reasons were better layer resolution (0.02mm vs 0.1 for the R2) and material support. I recently saw nylon prints and found them amazing -- I bet a lot of people would love to print their own soft, custom iPhone cases! In addition, the extruder head has two nozzles -- one large diameter one for fast infill, and another small diameter one for fine details. On top of that, they will be supporting dual extruder heads soon, which means I'll be able to print support material out of dissolvable PVA and HIPS. They have put a lot of thought into the design of this machine -- only time will tell if they can deliver. I'm a beta tester, which means I'll get my unit in January 2014. I cannot wait. This machine should be truly awesome... and if it delivers, it looks like I'll have a few printers to sell soon.

Wednesday, December 18, 2013

ShopBot fun

For SLAS 2014, my company is going to build a custom booth. You know, because we just roll like that. It turns out that the custom tabletops that would normally be really expensive fit on the ShopBot (just barely), so I was tasked with running the job.

Then we made it over to TechShop, got Eric his $25 guess pass, and unloaded the material. I love how TechShop has everything you need -- we found one of those Home Depot-like carts and used it to get the raw materials over to the machine.

Getting the material aligned properly wasn't too bad. After homing the X&Y axes to their proximity switches, I moved to the far end of Y (48") and then commanded a 96" X move. We watched the bit as it traveled over the end of the bamboo, and believe it or not, our first try was pretty much dead-on! After drilling four brass screws through the wood and sacrifial layer and into the leveling bed, we were finally ready to start! This is where the wheels came off.

I really need to post screenshots, but the short story is that ShopBot came in last night to perform a software upgrade. That's great and all, but they never bothered to tell any TechShop staff how to iuse it! Man, I'm getting really sleepy so I have to make this quick. After selecting the file and clicking start, a dialog pops up. It has a yellow square next to the part filename, with what looked like a "!" inside. So that means we have a problem, right? Well, normally I wouldn't have looked at the yellow box if the dialog had a Start button in it. Instead, it had a cancel button. So we thought it might have something to do with my .sbp being in mm instead of inches, yada yada yada. Apparently, TechShop SF had the same problem last night and couldn't run the machines. In the end, the yellow exclamation point was really an I with a _ underneath it. Seriously??? It turned out that you juse have to click the Start button again and then things magically worked.

Yesterday, I went to the TechShop to generate and verify the toolpath. I haven't used the software in a while, but got through it with a little bit of help. In this post, I just want to record the little tidbits of info I re-learned so that two years from now, I will be able to recall the necessary info.

First, I got the DXF in AutoCad R12 format to be on the safe side. Then I created a new project in VCarve Pro 7.0. Since the DXF was in mm, I set the project to be in mm as well.

The important thing to remember with the software is setting up the origins and XY definition properly. The origin should be in the lower-left corner.

I then used Import Vectors and specified the DXF. It might not appear on-screen, but hitting F9 will auto-center the part. Awesomely useful!

I'll jump ahead a little and talk about a problem that I had. After generating the toolpath, I noticed that the endmill was doing something weird. While the bit was supposed to cut on the outside of the part, in a few places it was actually flipping to the inside! In the end, it turned out that some points on the path were not joined. So after breaking the path up into discret curves and using the Join function in VCarve Pro, this problem went away.

Another part that gave me problems was the exporting of the ShopBot toolpath file. Most normal software packages put something like that under File -> Export, or File -> Save as, but in this case, there's a "Save Toolpath" button that appears when you close the preview window. Ok. Hopefully I won't make that mistake next time.

After loading the .sbp in the ShopBot software and previewing the cuts, I was happy and it was time to call it a day.

This morning, Eric (coworker) and I stopped by MacBeath to pick up the wood for the tabletops. Instead of mahogany plywood, Eric decided to try bamboo because it would preclude the need for veneer or any other finishing strips to cover the edge of the plywood. This is where a minivan really shines -- you can fit a stack of 4' x 8' pieces of plywood in a Honda Odyssey without any problems! Sweet!

After loading the .sbp in the ShopBot software and previewing the cuts, I was happy and it was time to call it a day.

This morning, Eric (coworker) and I stopped by MacBeath to pick up the wood for the tabletops. Instead of mahogany plywood, Eric decided to try bamboo because it would preclude the need for veneer or any other finishing strips to cover the edge of the plywood. This is where a minivan really shines -- you can fit a stack of 4' x 8' pieces of plywood in a Honda Odyssey without any problems! Sweet!

Then we made it over to TechShop, got Eric his $25 guess pass, and unloaded the material. I love how TechShop has everything you need -- we found one of those Home Depot-like carts and used it to get the raw materials over to the machine.

Getting the material aligned properly wasn't too bad. After homing the X&Y axes to their proximity switches, I moved to the far end of Y (48") and then commanded a 96" X move. We watched the bit as it traveled over the end of the bamboo, and believe it or not, our first try was pretty much dead-on! After drilling four brass screws through the wood and sacrifial layer and into the leveling bed, we were finally ready to start! This is where the wheels came off.

I really need to post screenshots, but the short story is that ShopBot came in last night to perform a software upgrade. That's great and all, but they never bothered to tell any TechShop staff how to iuse it! Man, I'm getting really sleepy so I have to make this quick. After selecting the file and clicking start, a dialog pops up. It has a yellow square next to the part filename, with what looked like a "!" inside. So that means we have a problem, right? Well, normally I wouldn't have looked at the yellow box if the dialog had a Start button in it. Instead, it had a cancel button. So we thought it might have something to do with my .sbp being in mm instead of inches, yada yada yada. Apparently, TechShop SF had the same problem last night and couldn't run the machines. In the end, the yellow exclamation point was really an I with a _ underneath it. Seriously??? It turned out that you juse have to click the Start button again and then things magically worked.

Here are some photos of the machine in motion.

Bamboo sure cuts nicely! I think I will use it for my next projects.

Here's how it looks after routing and on the Item frame the guys designed:

Wednesday, November 27, 2013

PCBs arrived!

Today my PCBs from oshpark came in. Check 'em out!

My Replicator 2 has been really busy running makexyz jobs, and work has been a little crazy, so it haven't been able to tinker much. I am currently learning more about the TI MSP430, because I think it's the perfect micro to power my laser tag project. More to come later...

Friday, November 22, 2013

Sidetracked...

makexyz has had me sidetracked a bit. I recently got a message from someone that wanted 150 pieces made. It was a pretty cool part and had a letter surrounded by multiple rings. When removed from the platform, the support material would break free from the axle and the rings would spin independently. I didn't have the right color and started to look around for local sources of Makerbot PLA. It turns out that the Microsoft Store sells it online, plus shipping is free! It's a way better deal than through Makerbot! While I waited for confirmation from the potential customer, I did some test prints to verify that I could produce these parts in time. The good news is that the Replicator 2 didn't disappoint, but the bad news was that the customer backed out.

On the bright side of things, this meant that I'd have time to focus on OnSLaughT and other projects. I made a few tweaks to the magazine and grip assembly, as well as the release mechanism. It's definitely getting closer to something that I think will work. I need to change the dimensions a bit so that the spring will fit inside of the release mechanism.

One other project I have left over from the summer is internet-enabling our Honeywell security system. While looking for DIY projects that accomplished this task, I came across a $119 product called EnvisaLink 3 that does pretty much everything I want! You hook it into your existing Honeywell Vista security system, connect it to your network, and then it will be capable of sending you emails / SMS whenever a specified event occurs. For example, I can be notified whenever the alarm is triggered, or I can simply be notified any time a window or door is opened. So this isn't really a maker project, as I just have to hook up some wires, but that in itself almost turned into yet another project. Check out this wiring:

What a mess, right? Just looking at it made me nervous -- one day I might sneeze and some wires would come off, and I'd have no idea how to fix it. To make matters worse, the EnvisaLink 3 needed to tap into the four most-occupied terminals in the box! My first thought was to take my newly-acquired Kicad skills and use them to produce a custom PCB that would make it easier to manage the multiple connections. Certainly this is something that a simple piece of DIN rail and Phoenix Contact terminal blocks could handle, but not as fun.

Well, while reading up on the wiring, I learned that the alarm system has an auxiliary "zone doubling" accessory that allows us to support more than 8 sensors. It turned out that the 4 terminal positions I had to tap into were also available in the zone-doubling accessory and used a standard 0.1" header! Today I hit HSC and picked up the parts I needed to complete the wiring. In case you live in the Bay Area and don't know about HSC, it's electronics surplus heaven there. They have so much stuff and it's pretty cheap. Power resistors, DC converters, scopes, connectors, wires, SMT stuff, you name it. Here are a couple of pics I snapped today:

Anyhow, I got it all wired up and stuck the EnvisaLink 3 into a 3D-printed case I whipped up this evening. Perfect fit on the first try and gave a satisfying snap as I popped it onto the chamfered pegs!

Now I just have to figure out how to complete the configuration and get my alarm system online! On the internet, that is.

On the bright side of things, this meant that I'd have time to focus on OnSLaughT and other projects. I made a few tweaks to the magazine and grip assembly, as well as the release mechanism. It's definitely getting closer to something that I think will work. I need to change the dimensions a bit so that the spring will fit inside of the release mechanism.

One other project I have left over from the summer is internet-enabling our Honeywell security system. While looking for DIY projects that accomplished this task, I came across a $119 product called EnvisaLink 3 that does pretty much everything I want! You hook it into your existing Honeywell Vista security system, connect it to your network, and then it will be capable of sending you emails / SMS whenever a specified event occurs. For example, I can be notified whenever the alarm is triggered, or I can simply be notified any time a window or door is opened. So this isn't really a maker project, as I just have to hook up some wires, but that in itself almost turned into yet another project. Check out this wiring:

What a mess, right? Just looking at it made me nervous -- one day I might sneeze and some wires would come off, and I'd have no idea how to fix it. To make matters worse, the EnvisaLink 3 needed to tap into the four most-occupied terminals in the box! My first thought was to take my newly-acquired Kicad skills and use them to produce a custom PCB that would make it easier to manage the multiple connections. Certainly this is something that a simple piece of DIN rail and Phoenix Contact terminal blocks could handle, but not as fun.

Well, while reading up on the wiring, I learned that the alarm system has an auxiliary "zone doubling" accessory that allows us to support more than 8 sensors. It turned out that the 4 terminal positions I had to tap into were also available in the zone-doubling accessory and used a standard 0.1" header! Today I hit HSC and picked up the parts I needed to complete the wiring. In case you live in the Bay Area and don't know about HSC, it's electronics surplus heaven there. They have so much stuff and it's pretty cheap. Power resistors, DC converters, scopes, connectors, wires, SMT stuff, you name it. Here are a couple of pics I snapped today:

Anyhow, I got it all wired up and stuck the EnvisaLink 3 into a 3D-printed case I whipped up this evening. Perfect fit on the first try and gave a satisfying snap as I popped it onto the chamfered pegs!

Now I just have to figure out how to complete the configuration and get my alarm system online! On the internet, that is.

Tuesday, November 19, 2013

Poorly timed blackout!

Fortunately, I just finished some prints for makexyz customers! That last print took almost five hours, and I would have been majorly bummed if I had to reprint it from scratch.

I finally got around to revising the laser tag models for the magazine release parts, and as soon as I started to print them, the power went out. Time to get that UPS for the printer! Well, maybe tomorrow morning I will be able to try again before I have to go to work.

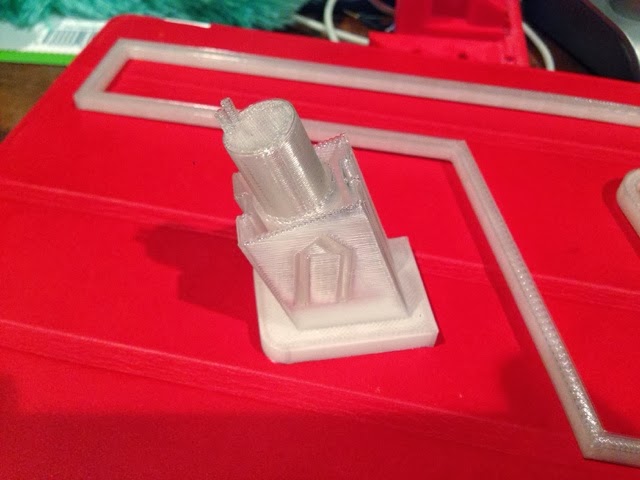

Here's what the parts look like.

Thursday, November 14, 2013

I never realized that making basic PCBs could be so easy!

I've only made a few PCBs before. One was a breakout board for the gauge electronics behind the center console in my Evo. The other was a Pololu-based stepper driver board intended to be a drop-in replacement for the MakerBot Cupcake electronics. Both were made using the proprietary software from PCBExpress. I actually really liked that software because it was super intuitive. I never even had to pick up a user manual to get my boards made. I just drew the schematic, exported to the PCB editor, then clicked Order and the boards arrived at my doorstep a week later! My only other experience was making a special EEPROM adapter for NSX ECUs, which was done on Protel DXP. That particular project required help from our board designers at work, because I had no clue what I was doing! And it was that PCB that, until today, made me think that real PCB work would always be beyond my abilities.

I can't remember how I found out about Chris Gammell's new Contextual Electronics website, but it was probably from one of the RSS feeds. In any case, I *really* wanted to take his course, but being able to dedicate 10 weeks is pretty tough with all of the things going on. Needless to say, I was thrilled when I received one of his emails, announcing the "Getting to Blinky" series on Youtube. For programmers out there, it's kind of like the EE equivalent of Hello World. Now, while Hello World on any new programming language doesn't excite me very much, being able to blink an LED via my own PCB is. So this afternoon I decided to just sit down and work through Chris' 7 videos to learn KiCad, and open source schematic capture and PCB design tool.

The courses are laid out very well, and the breaks between them are logical. If you weren't able to sit down and power through all of them at once, I think you would have a very easy time picking up wherever you had last left off. Chris seems like a pretty soft-spoken guy, and I definitely had to crank up the volume on my speakers to be able to hear him clearly. Other than that, the videos themselves are well-produced. The screencast is clear, and I especially like how the keystrokes he's using are displayed on-screen. This is very useful because KiCad is very keystroke-intensive. I think you are much better off learning the keystrokes than trying to find the various commands in the menus and toolbar icons (most of which don't really make sense to me).

Perhaps the only thing I would have liked in the videos was more cues that he's going to click on an important toolbar icon or introduce a new keystroke. When working in KiCad on my other monitor, I think the process would have been smoother if I knew when to glance over at what Chris was doing. I had to frequently rewind the videos to try to catch which button / keys he was pressing. I guess some people do this naturally to begin with -- i.e. watch a bit, pause, do the steps, unpause. I happen to like to do things at the same time, and it was a little difficult. That said, all of the content you could possibly need is there in the videos, and you will learn how to use the fundamental KiCad tools!

KiCad seems like a very powerful tool, and it never ceases to amaze me what these open source software packages can do, at no cost to us users! It has its quirks -- sometimes keystrokes wouldn't quite work, like V for via was failing during the routing session, and I had the darndest time trying to delete lines from my drawings. But in the end, everything worked out. By far the weirdest issue was with the footprint creation. I couldn't close the editor because I had to save the footprint, but I couldn't save the footprint because it wasn't associated with a library. This was the weirdest problem I've ever seen, and fortunately Chris ran into the same problem during his video... and that's the best part -- you get to see a real error when it happens, and have someone actually explain to you how to get around it! Can you imagine other edited tutorials that might have completely glossed over or removed this error from the video, leaving you scratching your head? I can, and it would really suck.

Anyhow, here's how the course is broken down:

I can't thank Chris enough for providing us with some free, extremely useful videos to help get some of us kickstarted with the PCB design process. I do hope that this gets those whom are on the fence about joining his course to sign up and go for it!

Oh, and check out my version of Getting to Blinky: (note that I didn't care about how bad my battery holder outline looked, nor did I size the pads and spacing exactly right, and I didn't follow the directions and move the component identifiers -- I just wanted to see the board!)

I promise to do better on my new two projects -- a new stepper board based on the ST L6470, and OnSLaughT, which is the new name I have given to my Open Source Laser Tag project.

I can't remember how I found out about Chris Gammell's new Contextual Electronics website, but it was probably from one of the RSS feeds. In any case, I *really* wanted to take his course, but being able to dedicate 10 weeks is pretty tough with all of the things going on. Needless to say, I was thrilled when I received one of his emails, announcing the "Getting to Blinky" series on Youtube. For programmers out there, it's kind of like the EE equivalent of Hello World. Now, while Hello World on any new programming language doesn't excite me very much, being able to blink an LED via my own PCB is. So this afternoon I decided to just sit down and work through Chris' 7 videos to learn KiCad, and open source schematic capture and PCB design tool.

The courses are laid out very well, and the breaks between them are logical. If you weren't able to sit down and power through all of them at once, I think you would have a very easy time picking up wherever you had last left off. Chris seems like a pretty soft-spoken guy, and I definitely had to crank up the volume on my speakers to be able to hear him clearly. Other than that, the videos themselves are well-produced. The screencast is clear, and I especially like how the keystrokes he's using are displayed on-screen. This is very useful because KiCad is very keystroke-intensive. I think you are much better off learning the keystrokes than trying to find the various commands in the menus and toolbar icons (most of which don't really make sense to me).

Perhaps the only thing I would have liked in the videos was more cues that he's going to click on an important toolbar icon or introduce a new keystroke. When working in KiCad on my other monitor, I think the process would have been smoother if I knew when to glance over at what Chris was doing. I had to frequently rewind the videos to try to catch which button / keys he was pressing. I guess some people do this naturally to begin with -- i.e. watch a bit, pause, do the steps, unpause. I happen to like to do things at the same time, and it was a little difficult. That said, all of the content you could possibly need is there in the videos, and you will learn how to use the fundamental KiCad tools!

KiCad seems like a very powerful tool, and it never ceases to amaze me what these open source software packages can do, at no cost to us users! It has its quirks -- sometimes keystrokes wouldn't quite work, like V for via was failing during the routing session, and I had the darndest time trying to delete lines from my drawings. But in the end, everything worked out. By far the weirdest issue was with the footprint creation. I couldn't close the editor because I had to save the footprint, but I couldn't save the footprint because it wasn't associated with a library. This was the weirdest problem I've ever seen, and fortunately Chris ran into the same problem during his video... and that's the best part -- you get to see a real error when it happens, and have someone actually explain to you how to get around it! Can you imagine other edited tutorials that might have completely glossed over or removed this error from the video, leaving you scratching your head? I can, and it would really suck.

Anyhow, here's how the course is broken down:

- Introduction

- Symbol Creation with the Component Library

- Schematic Creation with EEschema

- Part Association with CvPcb

- Creating Footprints with the Module Editor

- PCB Layout with PCBnew

- Output Files and Making Your Board

I can't thank Chris enough for providing us with some free, extremely useful videos to help get some of us kickstarted with the PCB design process. I do hope that this gets those whom are on the fence about joining his course to sign up and go for it!

Oh, and check out my version of Getting to Blinky: (note that I didn't care about how bad my battery holder outline looked, nor did I size the pads and spacing exactly right, and I didn't follow the directions and move the component identifiers -- I just wanted to see the board!)

I promise to do better on my new two projects -- a new stepper board based on the ST L6470, and OnSLaughT, which is the new name I have given to my Open Source Laser Tag project.

Wednesday, November 13, 2013

More SmartJars work...

I haven't been putting out new designs for the laser tag project lately, because I've been obsessed with getting the SmartJars insert to be financially feasible. I finally have a part that I think makes sense, but we'll just have to see if anyone decides to pick up a set. I went through several iterations of the design to get a part that wastes less material, yet feels sturdy enough to use.

The open source hardware I'm really excited about is my SmartJars carousel, because it's a perfect opportunity to re-acquaint myself with OpenSCAD. I used to use this amazing software a few years ago to make things parametrically. This awesome software package allows you to write code that translates into 2D and 3D objects. I only use it for things that I want to produce on the laser cutter, so this means 2D stuff.

Before OpenSCAD, I would create a 3D model in Alibre Design, and then create a drawing. Then I would export this drawing to DXF and import it into CorelDraw. An alternative way to design parts is directly in CorelDraw itself, but this can be painful for all but the simplest projects. My 56 state quarter frame was done entirely in CorelDraw, but since it was just a bunch of circles, it wasn't a big deal.

The SmartJars carousel is the perfect application for OpenSCAD. Once complete, you will be able to specify how many SmartJars on a panel (rows and columns), and how many panels in the carousel. With this information, OpenSCAD will allow you to output DXFs for the panel and top and bottom carouself pieces. Each SmartJar panel will interlock and screw into the top and bottom panels as well! Check it out (I know that the holes aren't centered yet...)

Once I get this done and make the carousel, I have a really cool v2 already in mind. :)

The open source hardware I'm really excited about is my SmartJars carousel, because it's a perfect opportunity to re-acquaint myself with OpenSCAD. I used to use this amazing software a few years ago to make things parametrically. This awesome software package allows you to write code that translates into 2D and 3D objects. I only use it for things that I want to produce on the laser cutter, so this means 2D stuff.

Before OpenSCAD, I would create a 3D model in Alibre Design, and then create a drawing. Then I would export this drawing to DXF and import it into CorelDraw. An alternative way to design parts is directly in CorelDraw itself, but this can be painful for all but the simplest projects. My 56 state quarter frame was done entirely in CorelDraw, but since it was just a bunch of circles, it wasn't a big deal.

The SmartJars carousel is the perfect application for OpenSCAD. Once complete, you will be able to specify how many SmartJars on a panel (rows and columns), and how many panels in the carousel. With this information, OpenSCAD will allow you to output DXFs for the panel and top and bottom carouself pieces. Each SmartJar panel will interlock and screw into the top and bottom panels as well! Check it out (I know that the holes aren't centered yet...)

Once I get this done and make the carousel, I have a really cool v2 already in mind. :)

Saturday, November 9, 2013

Worked on my SmartJars accessory design today

There's this awesome little Kickstarter project I backed that just got funded recently. It's called SmartJars, and I saw them for the first time at MakerFaire this year. The product is a nifty translucent jar that has a holder that snaps into ordinary pegboard, like this:

As you can see in the photo above, I've used the samples they sent me to start organizing the boys' Legos. It is pretty awesome for this, and I actually plan to make a spinning SmartJar Tower soon. This would allow them to have a ton of Legos on their table and hopefully keep them more organized than when we just throw them into large bins (this drives me insane, by the way). I'll likely make the tower out of hardboard or baltic birch plywood, because ordinary pegboard from Home Depot is just warped pieces of crap.

The one thing I had an issue with was the size -- small Legos aren't worth putting into one SmartJar because they take up so little space. I could group 1x1 Legos into the same SmartJar, but then I'd have to sift through them, which defeats the point.

I spent a lot of time iterating over my SmartJar accessory, which nicely partitions it into multiple sections. I have three designs -- 2, 3, and 4 compartment versions. Here's what the four-compartment model looks like:

It's a very nice looking piece. I made it on my Replicator 2 out of PLA. The great thing about using MakerBot's PLA is that it is food-grade, so people could use this for separating things like spices that aren't a powder (like peppercorns).

Anyhow, check out what it looks like in a SmartJar, and separating Legos, which was the original intent of the design:

And no spilling!

I'd like to put these up on etsy, since some SmartJars customers might want a few. The problem is that they are really expensive to make. I'm not sure if anyone is willing to fork out $5.00 to get four compartments out of a $2.50 SmartJar. If they were popular enough, I would start my own Kickstarter project and make my own mold, but I really don't have time for that.

As you can see in the photo above, I've used the samples they sent me to start organizing the boys' Legos. It is pretty awesome for this, and I actually plan to make a spinning SmartJar Tower soon. This would allow them to have a ton of Legos on their table and hopefully keep them more organized than when we just throw them into large bins (this drives me insane, by the way). I'll likely make the tower out of hardboard or baltic birch plywood, because ordinary pegboard from Home Depot is just warped pieces of crap.

The one thing I had an issue with was the size -- small Legos aren't worth putting into one SmartJar because they take up so little space. I could group 1x1 Legos into the same SmartJar, but then I'd have to sift through them, which defeats the point.

I spent a lot of time iterating over my SmartJar accessory, which nicely partitions it into multiple sections. I have three designs -- 2, 3, and 4 compartment versions. Here's what the four-compartment model looks like:

It's a very nice looking piece. I made it on my Replicator 2 out of PLA. The great thing about using MakerBot's PLA is that it is food-grade, so people could use this for separating things like spices that aren't a powder (like peppercorns).

Anyhow, check out what it looks like in a SmartJar, and separating Legos, which was the original intent of the design:

And no spilling!

I'd like to put these up on etsy, since some SmartJars customers might want a few. The problem is that they are really expensive to make. I'm not sure if anyone is willing to fork out $5.00 to get four compartments out of a $2.50 SmartJar. If they were popular enough, I would start my own Kickstarter project and make my own mold, but I really don't have time for that.

Friday, November 8, 2013

My "live" blog about getting Galago up and running

My goal tonight it to get the Galago up and running with the Logiblock IDE. I expect it to be a little rough around the edges, as development isn't complete, but there's only one way to find out! I'm going to approach this post like a "live blog". Obviously, this isn't a live stream, nor will I timestamp everything... instead I'm just going to enter everything I do, along with any errors or results that I observe. At the end of the post, hopefully I'll be able to see blinking LEDs!

First, here's a pic of the Galago + ledboard:

First, here's a pic of the Galago + ledboard:

- Went to https://github.com/OutbreakInc/Galago/wiki/Getting-started-guide

- Downloaded node-webkit for win32

- Just in case, I right-clicked on the zip -> selected Properies -> clicked Unblock so that the included EXE and DLLs would also be unblocked by Windows.

- Extracted to d:\galago\node-webkit

- Downloaded the Logiblock IDE launcher and left in my downloads folder

- Downloaded node.js and installed it

- Downloaded the Logiblock platform

- Extracted the files with 7-zip to d:\galago\logiblock-platform

- Downloaded the Galago USB drivers

- Extracted to d:\galago\usbdrivers

- NOTE: right-clicking Galago.inf and selecting "Install" does not work on Windows 7 x64. You have to run installer_x64.exe instead (or so I think... haven't tested it yet!)

- opened command prompt

- mkdir d:\galago\projects\test

- cd d:\galago\projects\test

- node d:\galago\logiblock-platform\bin\sdk.js --init

- Sure enough, just like in Kuy's video it downloaded a bunch of stuff and I ended up with this screen:

- I think it's time to connect the board! Plugged it in, and... didn't work.

- So I went to the Windows Device Manager and installed it there -- just right click on Galago, select Update Driver, then point Windows to the folder. In my case, I just specified d:\galago since it will search subfolders by default.

- Success! Now Galago is recognized by my OS.

- The wiki then says "to build and then download firmware to a connected Galago, pass the --install argument". I found it strange that it didn't say which project to install, but ok.

- That didn't work, it said "Could not open module JSON file". I assume I was supposed to pass the project path?

- Ah HA! Ok, yes, the correct command for my project "test" was node ..\logiblock-platform\bin\sdk.js --install test

- Oh, actually, I just realized that I was supposed to send the command from the project folder itself! My bad.

- Ok, so I didn't know what to do next. I forgot to pass the --debug switch, and ended up with a blank screen. I typed ctrl-z and enter to try to exit, but it didn't bring me back to the command prompt. Gonna try again now with a new command prompt... no love, didn't work. Here's my screen:

- For some reason, I'm not getting a (gdb) prompt at all. I checked the project folder that was generated with the --init switch, and the main.cpp looks legit to me.

Playing with custom springs

Springs can be pretty expensive, especially if you don't know exactly what you want and have to experiment with different sizes and spring rates. Google to the rescue -- there was an Instructable on how to make your own springs! It looked ridiculously easy, and it was! I ordered some stainless steel spring back wire from McMaster and whipped up a test spring in less than 15 seconds.

When I figure out what I size and spacing I need, I'll print a custom drill jig so that I can make every spring for the magazine release as identical as possible.

When I figure out what I size and spacing I need, I'll print a custom drill jig so that I can make every spring for the magazine release as identical as possible.

Thursday, November 7, 2013

Check out the barrel!

I think the barrel design for my laser tag gun looks pretty good. It has a Desert Eagle-ish angle to it and I attempted to add an accessory rail to it. The thought is that I will add in contacts for attaching various accessories. Maybe a GPS module. Maybe an OLED screen. Who knows?

I have to rev the lens tube to v2 so that it slides into the barrel. I also have to extend it to accommodate the trigger mechanism. Maybe I will get around to it tonight!

I love the Replicator 2 more and more with every passing day. This is truly an awesome printer.

Wednesday, November 6, 2013

Another potential Arduino-killer on the block

Though a bit delayed, the Galago project I backed on Kickstarter last year finally started shipping, and I received my boards yesterday. I am really excited to start playing with them, and soldered up the ethernet and led app boards today at work. Check them out!

Arduino is great because of the solid user base. Arduino sucks because of the "development environment" that makes debugging really just an exercise in patience as you pepper print statements throughout your code. Galago aims to improve things by offering hardware debugging. Once I get the tools in place, it will be interesting to see how it compares to other platforms that support debugging like Launchpad, Netduino, and the various PIC micros.

Arduino is great because of the solid user base. Arduino sucks because of the "development environment" that makes debugging really just an exercise in patience as you pepper print statements throughout your code. Galago aims to improve things by offering hardware debugging. Once I get the tools in place, it will be interesting to see how it compares to other platforms that support debugging like Launchpad, Netduino, and the various PIC micros.

Quick test of the LED tube

Looks pretty good to me! In the final version I will keep all of the slots in case the focal distance of the lenses change. I didn't have time to solder in a current-limiting resistor, but thankfully I have some current-limited cells so it wasn't necessary.

Tuesday, November 5, 2013

Testing out the 5V solenoid from SparkFun

Just got my 5V solenoids in the mail today, and seconds ago tested one on my power supply. At 5V it seems like it will give a reasonable kick, but at 3.3V it is a little weak. Not much I can do about this if I want to keep costs down. I could bump up the voltage but then I'd need to add another LiFePo4 cell, which adds another $3 to the COGS. The return spring is also a little weak. I am worried that the mini slide for the recoil effect will bind, but there's only one way to find out for sure!

Hole sizing not quite like the UP!

I just finished my lens "tube" that will collimate the light from an IR emitter. For now, I am going to test the focal distance with an ultra bright red LED with a 30 degree cone. I need to get an IR emitter with a 20 degree cone given my 30mm lens and 70mm focal distance (roughly). Too bad I didn't first check the accuracy of the hole with a yet print! The Replicator 2 printed a 4.4mm hole, whereas I modeled a 5mm hole. On the UP!, it probably would have been closer to 4.9mm.

UPDATE: Correction on the measurement -- I failed to realize that because I set the leveling such that the first layer gets smashed onto the build platform, the hole was smaller than it should have been. I measured the opposite side of the hole at 4.84mm, so it was pretty close after all. My bad!

UPDATE: Correction on the measurement -- I failed to realize that because I set the leveling such that the first layer gets smashed onto the build platform, the hole was smaller than it should have been. I measured the opposite side of the hole at 4.84mm, so it was pretty close after all. My bad!

I'll drill out the hole tomorrow and hook up the LED to a power supply once I am at the office. Stay tuned for pics!

A linear axis I made several months ago

Months and months ago, I backed a project called OpenRail on Kickstarter that I thought was going to be a complete gamechanger in the maker community. Imagine, a rail system that you can bolt onto standard extrusions to create linear axes! Totally awesome... but my excitement was short-lived. It turned out that not only was OpenRail a little more work to use with the extrusions I had on-hand, but OpenBuilds soon after came out with a Makerslide-like product called V-Slot.

The videos on the V-Slot webpage do a great job of explaining how the system works -- you should definitely watch them. V-Slot is an extremely affordable extrusion with a large number of accessories that make the creation of compound axes very simple. I stocked up a little on the parts and always keep extrusions, connectors, and the wheel kits in stock in case I want to build something.

My first test platform (pictured below) incorporated the 20x40 extrusion with modified motor mounts that I 3D printed on my UP! printer, as well as a 3D printed mounting plate:

I uploaded my mounting plate and motor mounts to Thingiverse.

The NEMA17 stepper is a cheap Lin Engineering model that I picked up on eBay years ago. I control the stage with the ST L6470 dev kit, and also added a linear encoder which is currently not used. The plan is to make a PCB that pairs something like a dspic33f with the L6470 to create a low cost motion control platform that supports position feedback with stepper motors. If you're using something like a Pololu or Allegro driver, give the L6470 a try -- it's pretty impressive once you figure out how to use it. I can embellish in another post if anyone is interested.

Here are some other closeup shots of mycheap linear stage:

The videos on the V-Slot webpage do a great job of explaining how the system works -- you should definitely watch them. V-Slot is an extremely affordable extrusion with a large number of accessories that make the creation of compound axes very simple. I stocked up a little on the parts and always keep extrusions, connectors, and the wheel kits in stock in case I want to build something.

My first test platform (pictured below) incorporated the 20x40 extrusion with modified motor mounts that I 3D printed on my UP! printer, as well as a 3D printed mounting plate:

I uploaded my mounting plate and motor mounts to Thingiverse.

The NEMA17 stepper is a cheap Lin Engineering model that I picked up on eBay years ago. I control the stage with the ST L6470 dev kit, and also added a linear encoder which is currently not used. The plan is to make a PCB that pairs something like a dspic33f with the L6470 to create a low cost motion control platform that supports position feedback with stepper motors. If you're using something like a Pololu or Allegro driver, give the L6470 a try -- it's pretty impressive once you figure out how to use it. I can embellish in another post if anyone is interested.

Here are some other closeup shots of mycheap linear stage:

Monday, November 4, 2013

Quick update

I got my lenses in from Korea today. If you can find what you need on eBay, that's definitely the way to go. I picked up 5 30mm x 70mm FD lenses for cheap... I can't remember how cheap, but they were probably $2 each. These will be used to collimate the IR LED beam to get longer range blasts.

Sidetracked by makexyz.com!

Have you ever known someone that said "hey, I came up with this idea, and someone else did it!". Then you tell your friend, "yeah, yeah, whatever". Well, I had one of those moments less than a year ago when I read about makexyz.com. Although I owned my own 3D printer, I was pretty annoyed that companies like Shapeways charge an arm and a leg for prints out of ABS and PLA. I can understand the premiums for printing out of powdered metal, but the common plastics shouldn't be so expensive. Anyhow, I thought making a site that connected printer owners with those that needed things printed would be cool. The problem was that I didn't have the ability to actually make such a site happen. Well, now makexyz is here and I think the site is fabulous.

Here's how it works -- a user that needs something printed can search for printer operators locally, and sort by price. He can look over the printer's specs and find something that is reasonably priced while meeting the needs for his part, like resolution, color, plastic type, etc. Then he sends the operator a request for quote and makexyz takes care of the rest. The invoicing system is built-in, and what I really love is how they add their commission to the final price. It's not like eBay where you sell your item and then have to pay eBay out of your own pocket. The commission is charged to the buyer instead.

Anyhow, these are the parts I was asked to print:

Yesterday's attempt at printing the screw piece failed because the part came off of the build platform. I resolved this issue by using painter's tape, which PLA bonds to nicely.

Unfortunately, PLA bonds a little too well to the blue tape, and that's the caveat of a service like makexyz.com. When I tried to remove the part from the platform, I broke it off! So if you have signed up to print a part that ends up being challenging in some way, you could actually lose money. I'm already almost at that point with these parts because I didn't charge enough up front. Most people talk about charging by the gram and also for energy usage, but I think there needs to be a scaling factor for time. Parts that require lots of time due to size or support structures are inherently a greater risk. Therefore, you need to charge more for these parts because there's always a chance that something bad is going to happen.

I have to work with the customer on this one to see how he wants to proceed. I've glued the piece together, and hopefully it will work, but with a 30% fill, this part might actually not be strong enough. I will also recommend that he reslice the part so I can print it without support material. I will also suggest that I refund his money and he find another person to print the part. This was a very good lesson for me!

Saturday, November 2, 2013

New release mechanism for magazine

So here's a cutaway view of my latest grip model. There's a nice amount of material so that the magazine will not bind inside of the grip. The magazine now has a bar with a notch in it that will hopefully catch on the to-be-designed release button. I haven't decided how to approach the spring loading for the magazine, but it will come to me once I have the release mechanism designed.

A quick review of the MakerBot Replicator 2

While I sit here and wait for another iteration of my OS Lazer Tag grip to print, I thought I'd just say a few things about the MakerBot Replicator 2, which I recently purchased via a sweet deal through Autodesk. In case you are thinking about getting one, now is the time to pull the trigger.

http://www.123dapp.com/education

I actually had a Form1 printer and it was sitting in the garage for a few weeks, completely unopened. I ended up assuming that it would be a less user-friendly experience for me. I tend to print in short bursts here and there, and leaving the resin idle in the reservoir just didn't feel right. On top of that, I was reading through the care instructions and I was a little worried about the special coating on the reservoir that can't be scratched, as that's what prevents the cured resin from sticking to it. I sold the printer on ebay at a small profit, and then reinvested the funds in the Replicator 2.

Let's just say that I'm extremely happy with my decision. I was an owner of the original MakerBot Cupcake, and MakerBot has really come a long way with their software and hardware. As expected, the Cupcake was an endless time sink, where I spent more time tweaking hardware and software settings than actually printing. I always had to buy upgraded parts from MakerGear to get the printer to print reliably. I ended up ditching the Cupcake and going with the PP3DP UP! printer, which I still have and love.

But ever since I picked up the Replicator 2, I have been running it non-stop. I am almost through my first spool of PLA and have yet to experience a bad print. There is slight warping on some of my parts, but all of my prints have completed and because of it, I'm making pretty decent progress on the design of my open source Lazer Tag system.

MakerWare is really quite nice. For some reason, slicing certain parts on Thingiverse takes forever, but everything I've done for my own projects have sliced very quickly. It's still not as fast as Simplify3D's Creator software, but the x3g files MakerWare creates actually work (which should be the case), whereas I haven't gotten Creator's output to work on the printer yet. I'm so glad that the days of using Skeinforge and Replicatorg are finally over. MakerWare really delivers on the experience that PP3DP gave us with the UP!, and it's even nicer. I like the print preview -- when printing parts for others, knowing how much filament is going to be used ahead of time, as well as print times, is really nice. My workflow has been entirely via SD card. Instead of risking issues with my PC crashing or losing power, I just save to SD on the PC and then print from SD on the Replicator 2. I absolutely love the fact that it has an LCD interface with intuitive menus.

The setup process via the LCD couldn't have been any easier. MakerBot did a nice job of the build platform leveling "wizard" by having the user first dial in the Z height with the nozzle directly over each thumbscrew. This just makes so much sense and it's a lot easier to set up than my first generation UP! printer. The Replicator 2 delivered a perfect first print right out of the box after leveling the platform.

My only gripe right now is the way that MakerBot is spooling their PLA. It's very tight and it seems like certain sections of the filament are either slightly kinked or twisted. I have to remember to loosen up the spool during prints to relieve the tension. Last night I had forgotten to do this and the filament snapped in the middle of the print. Fortunately, I was here and was able to recover. You also have to be careful when adding slack to the filament at the beginning of the spool, because it might actually unwind off of the spool and get caught on the spindle if you're not careful.

Ok, well the grip is almost done printing (gotta love the progress percentage display on the LCD!), so I'm going to stop my Replicator 2 review here, and will post pics of the next iteration of parts soon.

http://www.123dapp.com/education

I actually had a Form1 printer and it was sitting in the garage for a few weeks, completely unopened. I ended up assuming that it would be a less user-friendly experience for me. I tend to print in short bursts here and there, and leaving the resin idle in the reservoir just didn't feel right. On top of that, I was reading through the care instructions and I was a little worried about the special coating on the reservoir that can't be scratched, as that's what prevents the cured resin from sticking to it. I sold the printer on ebay at a small profit, and then reinvested the funds in the Replicator 2.

Let's just say that I'm extremely happy with my decision. I was an owner of the original MakerBot Cupcake, and MakerBot has really come a long way with their software and hardware. As expected, the Cupcake was an endless time sink, where I spent more time tweaking hardware and software settings than actually printing. I always had to buy upgraded parts from MakerGear to get the printer to print reliably. I ended up ditching the Cupcake and going with the PP3DP UP! printer, which I still have and love.

But ever since I picked up the Replicator 2, I have been running it non-stop. I am almost through my first spool of PLA and have yet to experience a bad print. There is slight warping on some of my parts, but all of my prints have completed and because of it, I'm making pretty decent progress on the design of my open source Lazer Tag system.

MakerWare is really quite nice. For some reason, slicing certain parts on Thingiverse takes forever, but everything I've done for my own projects have sliced very quickly. It's still not as fast as Simplify3D's Creator software, but the x3g files MakerWare creates actually work (which should be the case), whereas I haven't gotten Creator's output to work on the printer yet. I'm so glad that the days of using Skeinforge and Replicatorg are finally over. MakerWare really delivers on the experience that PP3DP gave us with the UP!, and it's even nicer. I like the print preview -- when printing parts for others, knowing how much filament is going to be used ahead of time, as well as print times, is really nice. My workflow has been entirely via SD card. Instead of risking issues with my PC crashing or losing power, I just save to SD on the PC and then print from SD on the Replicator 2. I absolutely love the fact that it has an LCD interface with intuitive menus.

The setup process via the LCD couldn't have been any easier. MakerBot did a nice job of the build platform leveling "wizard" by having the user first dial in the Z height with the nozzle directly over each thumbscrew. This just makes so much sense and it's a lot easier to set up than my first generation UP! printer. The Replicator 2 delivered a perfect first print right out of the box after leveling the platform.

My only gripe right now is the way that MakerBot is spooling their PLA. It's very tight and it seems like certain sections of the filament are either slightly kinked or twisted. I have to remember to loosen up the spool during prints to relieve the tension. Last night I had forgotten to do this and the filament snapped in the middle of the print. Fortunately, I was here and was able to recover. You also have to be careful when adding slack to the filament at the beginning of the spool, because it might actually unwind off of the spool and get caught on the spindle if you're not careful.

Ok, well the grip is almost done printing (gotta love the progress percentage display on the LCD!), so I'm going to stop my Replicator 2 review here, and will post pics of the next iteration of parts soon.

Yet another grip design

On this iteration, I went away from designing the grip as two separate pieces in favor of printing one piece. The advantage here is that I can easily mirror features from one side to the other, as well as get a good feel for the grip without having to join two pieces.

I added traction features to the sides and front of the grip. I also enlarged the bosses that go between the fingers. The grip needs to be more comfortable so I increased the radius of curvature all the way around. The rear curvature needs to change more so it's more like the Glock 17.

Next I will add the hole in the bottom for the battery magazine, and try to come up with an eject mechanism and way to add a custom spring.

Friday, November 1, 2013

Grips!

Well, the left side grip finished while I was sleeping last night. 😁

It's not bad for a first pass. It doesn't fit quite right over the gun's frame and it's also not nearly as comfortable as the Glock 17's grip, which is my baseline for comparison.

I am also rethinking the gun frame concept. I think I should try to incorporate the magazine slider features and release into the grips instead. We will see how this turns out with the next couple of iterations.

Wednesday, October 30, 2013

Magazine slide feature underway

I decided to kick off a fixed print so the frame has the right thickness. Here's what the grip might look like eventually.

Tuesday, October 29, 2013

Pics of my first Lazer Tag parts

Here is the gun frame I printed last night:

And here is the battery "magazine":

I made a quick rev 2, where I changed the thickess and length of the magazine. I figured that the battery should stick out more in case it ever needed replacement. I also shelled the upper portion to make it possible to include release tabs. You may also have noticed that the angle of the top is now perpendicular to the sides of the magazine. I did this because I felt that was the direction of the eject spring's force.

For rev 3, I will add more thickness so the tabs can be a little meatier. There also isn't enough space behind the tabs for proper disengagement. I also think it's time for a rev 2 of the gun frame. Most likely I will only print the handle and try to get the magazine to slide in and out a little.

Subscribe to:

Posts (Atom)

.JPG)