makexyz has had me sidetracked a bit. I recently got a message from someone that wanted 150 pieces made. It was a pretty cool part and had a letter surrounded by multiple rings. When removed from the platform, the support material would break free from the axle and the rings would spin independently. I didn't have the right color and started to look around for local sources of Makerbot PLA. It turns out that the Microsoft Store sells it online, plus shipping is free! It's a way better deal than through Makerbot! While I waited for confirmation from the potential customer, I did some test prints to verify that I could produce these parts in time. The good news is that the Replicator 2 didn't disappoint, but the bad news was that the customer backed out.

On the bright side of things, this meant that I'd have time to focus on OnSLaughT and other projects. I made a few tweaks to the magazine and grip assembly, as well as the release mechanism. It's definitely getting closer to something that I think will work. I need to change the dimensions a bit so that the spring will fit inside of the release mechanism.

One other project I have left over from the summer is internet-enabling our Honeywell security system. While looking for DIY projects that accomplished this task, I came across a $119 product called EnvisaLink 3 that does pretty much everything I want! You hook it into your existing Honeywell Vista security system, connect it to your network, and then it will be capable of sending you emails / SMS whenever a specified event occurs. For example, I can be notified whenever the alarm is triggered, or I can simply be notified any time a window or door is opened. So this isn't really a maker project, as I just have to hook up some wires, but that in itself almost turned into yet another project. Check out this wiring:

What a mess, right? Just looking at it made me nervous -- one day I might sneeze and some wires would come off, and I'd have no idea how to fix it. To make matters worse, the EnvisaLink 3 needed to tap into the four most-occupied terminals in the box! My first thought was to take my newly-acquired Kicad skills and use them to produce a custom PCB that would make it easier to manage the multiple connections. Certainly this is something that a simple piece of DIN rail and Phoenix Contact terminal blocks could handle, but not as fun.

Well, while reading up on the wiring, I learned that the alarm system has an auxiliary "zone doubling" accessory that allows us to support more than 8 sensors. It turned out that the 4 terminal positions I had to tap into were also available in the zone-doubling accessory and used a standard 0.1" header! Today I hit HSC and picked up the parts I needed to complete the wiring. In case you live in the Bay Area and don't know about HSC, it's electronics surplus heaven there. They have so much stuff and it's pretty cheap. Power resistors, DC converters, scopes, connectors, wires, SMT stuff, you name it. Here are a couple of pics I snapped today:

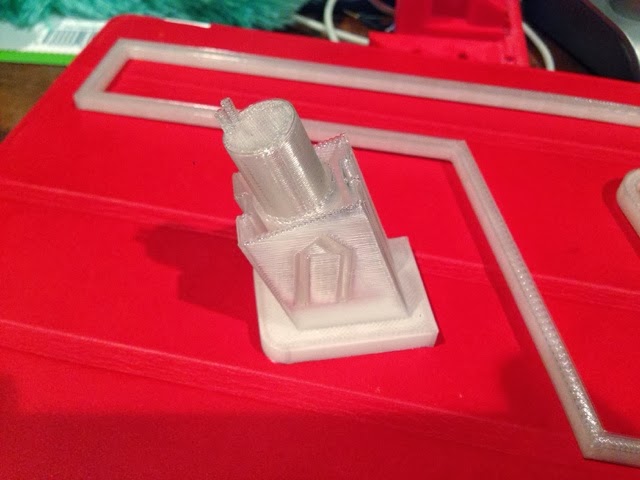

Anyhow, I got it all wired up and stuck the EnvisaLink 3 into a 3D-printed case I whipped up this evening. Perfect fit on the first try and gave a satisfying snap as I popped it onto the chamfered pegs!

Now I just have to figure out how to complete the configuration and get my alarm system online! On the internet, that is.

Showing posts with label replicator. Show all posts

Showing posts with label replicator. Show all posts

Friday, November 22, 2013

Saturday, November 2, 2013

New release mechanism for magazine

So here's a cutaway view of my latest grip model. There's a nice amount of material so that the magazine will not bind inside of the grip. The magazine now has a bar with a notch in it that will hopefully catch on the to-be-designed release button. I haven't decided how to approach the spring loading for the magazine, but it will come to me once I have the release mechanism designed.

A quick review of the MakerBot Replicator 2

While I sit here and wait for another iteration of my OS Lazer Tag grip to print, I thought I'd just say a few things about the MakerBot Replicator 2, which I recently purchased via a sweet deal through Autodesk. In case you are thinking about getting one, now is the time to pull the trigger.

http://www.123dapp.com/education

I actually had a Form1 printer and it was sitting in the garage for a few weeks, completely unopened. I ended up assuming that it would be a less user-friendly experience for me. I tend to print in short bursts here and there, and leaving the resin idle in the reservoir just didn't feel right. On top of that, I was reading through the care instructions and I was a little worried about the special coating on the reservoir that can't be scratched, as that's what prevents the cured resin from sticking to it. I sold the printer on ebay at a small profit, and then reinvested the funds in the Replicator 2.

Let's just say that I'm extremely happy with my decision. I was an owner of the original MakerBot Cupcake, and MakerBot has really come a long way with their software and hardware. As expected, the Cupcake was an endless time sink, where I spent more time tweaking hardware and software settings than actually printing. I always had to buy upgraded parts from MakerGear to get the printer to print reliably. I ended up ditching the Cupcake and going with the PP3DP UP! printer, which I still have and love.

But ever since I picked up the Replicator 2, I have been running it non-stop. I am almost through my first spool of PLA and have yet to experience a bad print. There is slight warping on some of my parts, but all of my prints have completed and because of it, I'm making pretty decent progress on the design of my open source Lazer Tag system.

MakerWare is really quite nice. For some reason, slicing certain parts on Thingiverse takes forever, but everything I've done for my own projects have sliced very quickly. It's still not as fast as Simplify3D's Creator software, but the x3g files MakerWare creates actually work (which should be the case), whereas I haven't gotten Creator's output to work on the printer yet. I'm so glad that the days of using Skeinforge and Replicatorg are finally over. MakerWare really delivers on the experience that PP3DP gave us with the UP!, and it's even nicer. I like the print preview -- when printing parts for others, knowing how much filament is going to be used ahead of time, as well as print times, is really nice. My workflow has been entirely via SD card. Instead of risking issues with my PC crashing or losing power, I just save to SD on the PC and then print from SD on the Replicator 2. I absolutely love the fact that it has an LCD interface with intuitive menus.

The setup process via the LCD couldn't have been any easier. MakerBot did a nice job of the build platform leveling "wizard" by having the user first dial in the Z height with the nozzle directly over each thumbscrew. This just makes so much sense and it's a lot easier to set up than my first generation UP! printer. The Replicator 2 delivered a perfect first print right out of the box after leveling the platform.

My only gripe right now is the way that MakerBot is spooling their PLA. It's very tight and it seems like certain sections of the filament are either slightly kinked or twisted. I have to remember to loosen up the spool during prints to relieve the tension. Last night I had forgotten to do this and the filament snapped in the middle of the print. Fortunately, I was here and was able to recover. You also have to be careful when adding slack to the filament at the beginning of the spool, because it might actually unwind off of the spool and get caught on the spindle if you're not careful.

Ok, well the grip is almost done printing (gotta love the progress percentage display on the LCD!), so I'm going to stop my Replicator 2 review here, and will post pics of the next iteration of parts soon.

http://www.123dapp.com/education

I actually had a Form1 printer and it was sitting in the garage for a few weeks, completely unopened. I ended up assuming that it would be a less user-friendly experience for me. I tend to print in short bursts here and there, and leaving the resin idle in the reservoir just didn't feel right. On top of that, I was reading through the care instructions and I was a little worried about the special coating on the reservoir that can't be scratched, as that's what prevents the cured resin from sticking to it. I sold the printer on ebay at a small profit, and then reinvested the funds in the Replicator 2.

Let's just say that I'm extremely happy with my decision. I was an owner of the original MakerBot Cupcake, and MakerBot has really come a long way with their software and hardware. As expected, the Cupcake was an endless time sink, where I spent more time tweaking hardware and software settings than actually printing. I always had to buy upgraded parts from MakerGear to get the printer to print reliably. I ended up ditching the Cupcake and going with the PP3DP UP! printer, which I still have and love.

But ever since I picked up the Replicator 2, I have been running it non-stop. I am almost through my first spool of PLA and have yet to experience a bad print. There is slight warping on some of my parts, but all of my prints have completed and because of it, I'm making pretty decent progress on the design of my open source Lazer Tag system.

MakerWare is really quite nice. For some reason, slicing certain parts on Thingiverse takes forever, but everything I've done for my own projects have sliced very quickly. It's still not as fast as Simplify3D's Creator software, but the x3g files MakerWare creates actually work (which should be the case), whereas I haven't gotten Creator's output to work on the printer yet. I'm so glad that the days of using Skeinforge and Replicatorg are finally over. MakerWare really delivers on the experience that PP3DP gave us with the UP!, and it's even nicer. I like the print preview -- when printing parts for others, knowing how much filament is going to be used ahead of time, as well as print times, is really nice. My workflow has been entirely via SD card. Instead of risking issues with my PC crashing or losing power, I just save to SD on the PC and then print from SD on the Replicator 2. I absolutely love the fact that it has an LCD interface with intuitive menus.

The setup process via the LCD couldn't have been any easier. MakerBot did a nice job of the build platform leveling "wizard" by having the user first dial in the Z height with the nozzle directly over each thumbscrew. This just makes so much sense and it's a lot easier to set up than my first generation UP! printer. The Replicator 2 delivered a perfect first print right out of the box after leveling the platform.

My only gripe right now is the way that MakerBot is spooling their PLA. It's very tight and it seems like certain sections of the filament are either slightly kinked or twisted. I have to remember to loosen up the spool during prints to relieve the tension. Last night I had forgotten to do this and the filament snapped in the middle of the print. Fortunately, I was here and was able to recover. You also have to be careful when adding slack to the filament at the beginning of the spool, because it might actually unwind off of the spool and get caught on the spindle if you're not careful.

Ok, well the grip is almost done printing (gotta love the progress percentage display on the LCD!), so I'm going to stop my Replicator 2 review here, and will post pics of the next iteration of parts soon.

Yet another grip design

On this iteration, I went away from designing the grip as two separate pieces in favor of printing one piece. The advantage here is that I can easily mirror features from one side to the other, as well as get a good feel for the grip without having to join two pieces.

I added traction features to the sides and front of the grip. I also enlarged the bosses that go between the fingers. The grip needs to be more comfortable so I increased the radius of curvature all the way around. The rear curvature needs to change more so it's more like the Glock 17.

Next I will add the hole in the bottom for the battery magazine, and try to come up with an eject mechanism and way to add a custom spring.

Friday, November 1, 2013

Grips!

Well, the left side grip finished while I was sleeping last night. 😁

It's not bad for a first pass. It doesn't fit quite right over the gun's frame and it's also not nearly as comfortable as the Glock 17's grip, which is my baseline for comparison.

I am also rethinking the gun frame concept. I think I should try to incorporate the magazine slider features and release into the grips instead. We will see how this turns out with the next couple of iterations.

Wednesday, October 30, 2013

Magazine slide feature underway

I decided to kick off a fixed print so the frame has the right thickness. Here's what the grip might look like eventually.

Tuesday, October 29, 2013

Pics of my first Lazer Tag parts

Here is the gun frame I printed last night:

And here is the battery "magazine":

I made a quick rev 2, where I changed the thickess and length of the magazine. I figured that the battery should stick out more in case it ever needed replacement. I also shelled the upper portion to make it possible to include release tabs. You may also have noticed that the angle of the top is now perpendicular to the sides of the magazine. I did this because I felt that was the direction of the eject spring's force.

For rev 3, I will add more thickness so the tabs can be a little meatier. There also isn't enough space behind the tabs for proper disengagement. I also think it's time for a rev 2 of the gun frame. Most likely I will only print the handle and try to get the magazine to slide in and out a little.

My new maker blog after the demise of Posterous

I wonder what it was that drew me to Posterous in the first place... Whatever it was, I certainly regret it because I can't remember where I had exported all of my past blogging data. I used Posterous for my infrequent progress reports on various projects, like 3D printing and my racing simulator. And now it's all gone! :( I guess it's time to try out Blogger and hope that it doesn't get axed like some other Google products.

The racing simulator was a pretty big project, but I finally have it at a point where it's completely functional. It might not look polished, but it does work. I'm looking forward to getting some seat time in it with the kids over the winter. Summer is just too hot to be sitting in a garage playing video games. I should post pictures later... maybe when I figure out how to make posts from my phone. I'm too lazy to do the photo transfer thing. ;)

I have decided to start a new project! My kids had some friends over last week, and we only had two Lazer Tag guns. I never bought more because the new Lazer Tag set (recently acquired by Nerf, I think?) is best experienced when you pair it with an iOS device. I don't know if it's required or not, but I don't have enough spare devices for the number of players I'd like to support, and the gun seems a little big. Our current Lazer Tag guns are also pretty unwieldy. So I decided that it would be worth creating some kind of open source Lazer Tag system.

Then I started to google a bit and came across Skirmos. It is a very recent project -- their Facebook page was created back in November 2012, and a post in September 2013 mentions that they are starting a Kickstarter campaign. I could wait to see what they are going to be offering for their pledge levels and just buy their system, or I could try to come up with my own. I've decided for the latter, though I will also keep up with them on FB and KS over the coming weeks.

My first issue with Skirmos (which is arguably one of their attractive characteristics for most people) is that you seem to strap it onto any gun you already have. This is great for a lot of reasons, but I'm looking for something that's easier for 2nd graders to run around with and not bang large guns around or outside of the house. We only have those large Nerf rifles and I know it just won't work.

I'm also looking for a semi-realistic experience for the guns. What I love about our current Lazer Tag guns is that you feel a kick when you pull the trigger, and to reload you have to "eject" the magazine. Totally awesome features IMO. I want to recreate this experience.

I started by taking measurements of my hand with my calipers. Given the ideal (or what I recall is the ideal) grip angle of 110deg, I made a quick sketch of a gun frame and printed it on the Replicator 2 so I could hold it in my hand. It actually came out pretty close -- after the fact I placed it on top of my airsoft replica of a Glock 17 and it was almost right-on. I also picked a reasonable LiFePO4 battery from batteryspace.com and printed out a model of that. Then I made a magazine to hold the battery. I wanted the battery in the magazine since that's a good place to put the weight, and it would make battery replacement easier. I need to change the model so that it has quick release tabs for easy removal from the gun.

Not a bad start for one night's work. I'll post pictures when I can do it from my phone. There's got to be an app for Blogger, right? ;)

The racing simulator was a pretty big project, but I finally have it at a point where it's completely functional. It might not look polished, but it does work. I'm looking forward to getting some seat time in it with the kids over the winter. Summer is just too hot to be sitting in a garage playing video games. I should post pictures later... maybe when I figure out how to make posts from my phone. I'm too lazy to do the photo transfer thing. ;)

I have decided to start a new project! My kids had some friends over last week, and we only had two Lazer Tag guns. I never bought more because the new Lazer Tag set (recently acquired by Nerf, I think?) is best experienced when you pair it with an iOS device. I don't know if it's required or not, but I don't have enough spare devices for the number of players I'd like to support, and the gun seems a little big. Our current Lazer Tag guns are also pretty unwieldy. So I decided that it would be worth creating some kind of open source Lazer Tag system.

Then I started to google a bit and came across Skirmos. It is a very recent project -- their Facebook page was created back in November 2012, and a post in September 2013 mentions that they are starting a Kickstarter campaign. I could wait to see what they are going to be offering for their pledge levels and just buy their system, or I could try to come up with my own. I've decided for the latter, though I will also keep up with them on FB and KS over the coming weeks.

My first issue with Skirmos (which is arguably one of their attractive characteristics for most people) is that you seem to strap it onto any gun you already have. This is great for a lot of reasons, but I'm looking for something that's easier for 2nd graders to run around with and not bang large guns around or outside of the house. We only have those large Nerf rifles and I know it just won't work.

I'm also looking for a semi-realistic experience for the guns. What I love about our current Lazer Tag guns is that you feel a kick when you pull the trigger, and to reload you have to "eject" the magazine. Totally awesome features IMO. I want to recreate this experience.

I started by taking measurements of my hand with my calipers. Given the ideal (or what I recall is the ideal) grip angle of 110deg, I made a quick sketch of a gun frame and printed it on the Replicator 2 so I could hold it in my hand. It actually came out pretty close -- after the fact I placed it on top of my airsoft replica of a Glock 17 and it was almost right-on. I also picked a reasonable LiFePO4 battery from batteryspace.com and printed out a model of that. Then I made a magazine to hold the battery. I wanted the battery in the magazine since that's a good place to put the weight, and it would make battery replacement easier. I need to change the model so that it has quick release tabs for easy removal from the gun.

Not a bad start for one night's work. I'll post pictures when I can do it from my phone. There's got to be an app for Blogger, right? ;)

Subscribe to:

Posts (Atom)